“ EXPERT IN CURVED ROOF AND WALL CLADDING ”

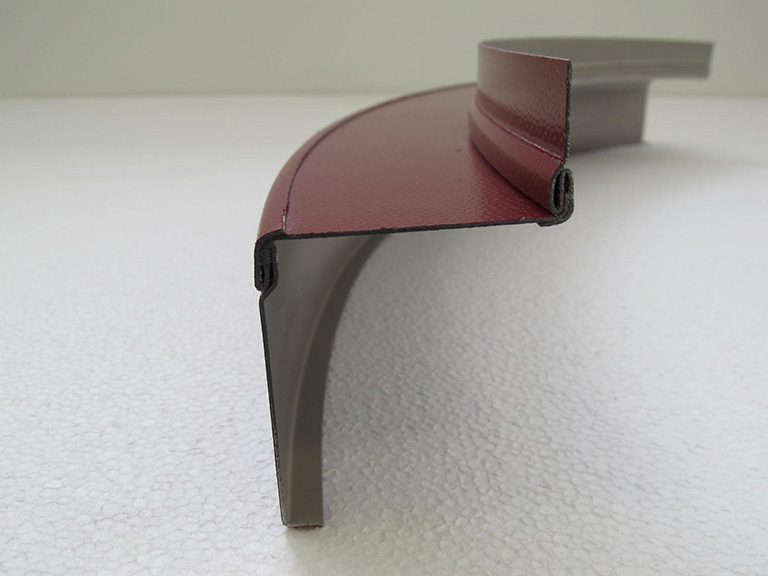

Curved sheet metal work

Dupral also specialises in producing every imaginable curved roof and wall cladding accessory’s from steel, aluminium, copper and zinc.

On the one hand: assembling round sheet metal work by means of folding.

On the other hand: producing round formed sections by means of crimp-curving.

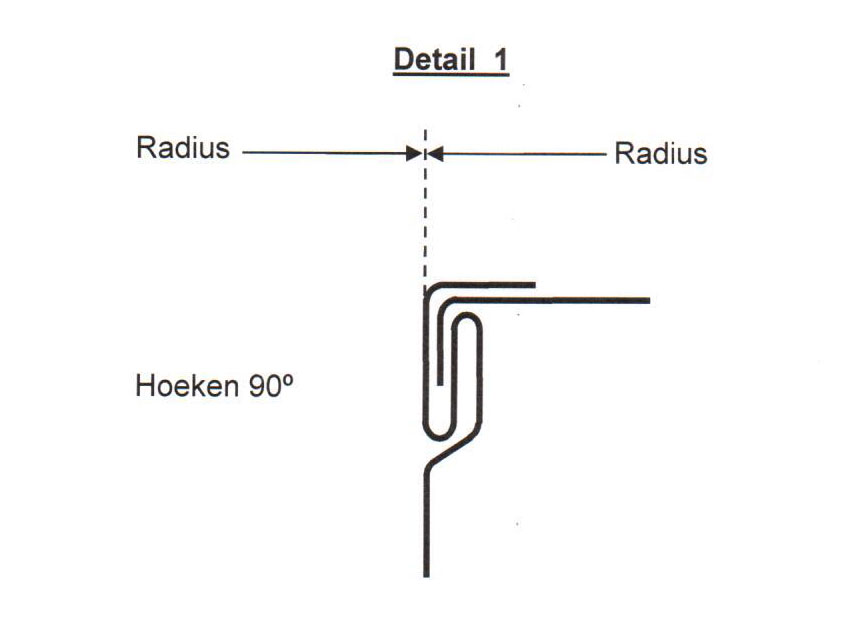

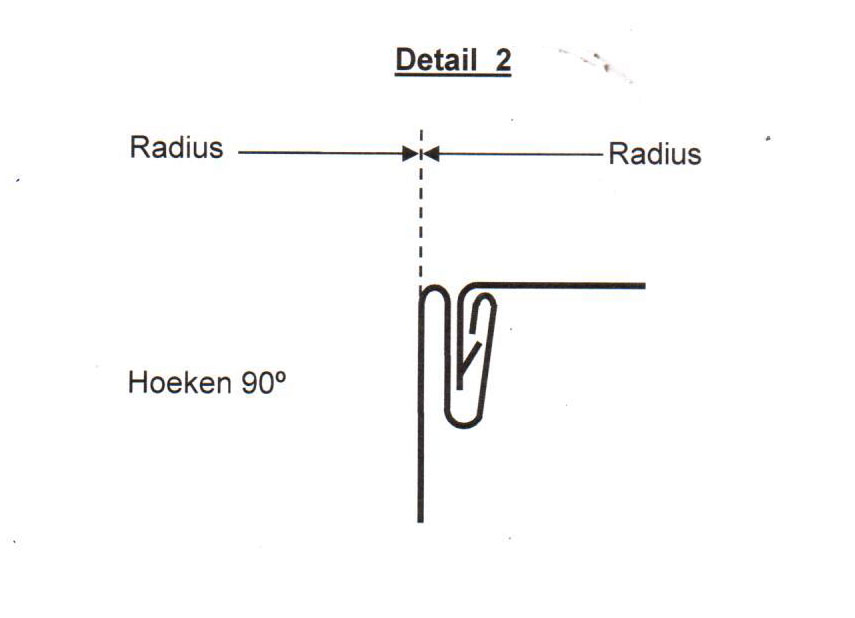

Folding Technique

Folding means that various components are folded together.

- The standard technique of Dupral is Detail 1.

- Detail 2 is possible in very specific cases.

Folding coping sections

Coping sections are made by folding and the process has few limitations. Folding means that various components are folded together, which for a coping section usually involves 4 to 5 components.

For larger sizes there is the option of bonding Eps to the inside, which results in a smoother appearance. Coping sections can be produced from steel, aluminium, copper and zinc. The maximum thickness is 1.0 mm and all angles have to be 90°.

Folding window finishing sections

Window finishing sections are made by folding. Folding means that various components are folded together, which for a window finishing section usually involves 4 to 5 components..

Window finishing sections can be produced from steel, aluminum, copper and zinc. The maximum thickness is 1.0 mm and all angles have to be 90°.

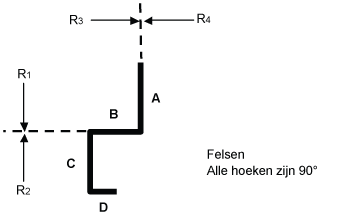

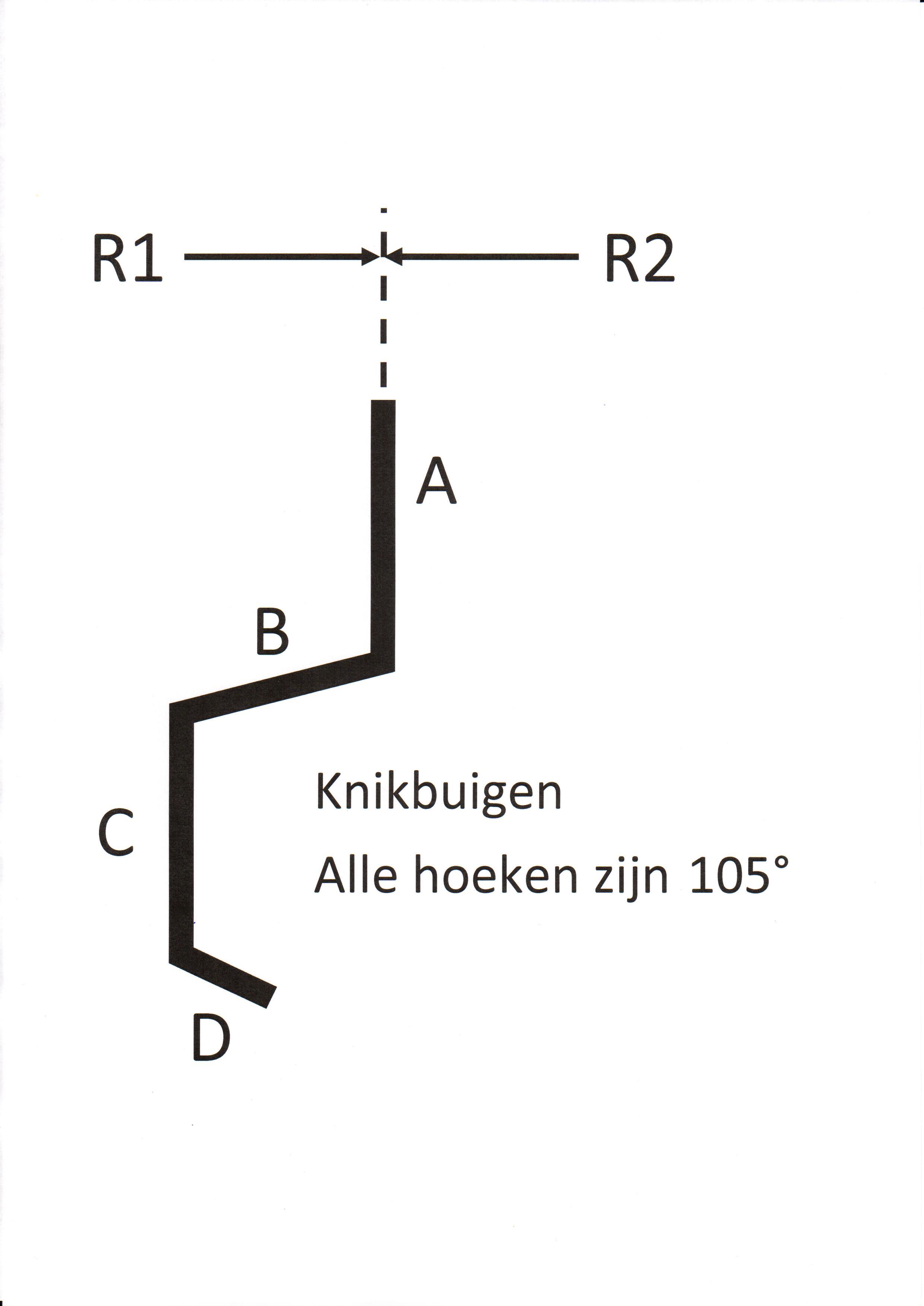

Folding external window sills

External window sills are made by folding and the process has few limitations. Folding means that various components are folded together, which for an external window sill usually involves 3 to 4 components.

External window sills can be produced from steel, aluminum, copper and zinc.

The maximum thickness is 1.0 mm and all angles have to be 90°.

SPECIFICATIONS:

| Minimum Sizes (folding): | |

| size A | 5 mm |

| size B | 30 mm |

| size C | 30 mm |

| size D | 5 mm |

| radius | 250 mm |

| angle | 90 ° |

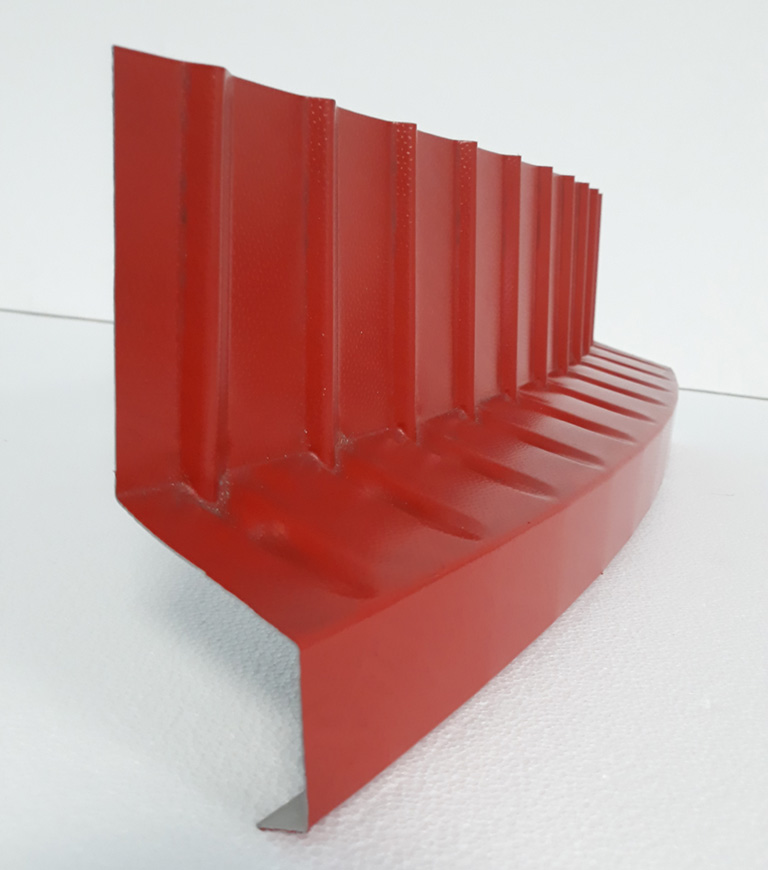

Crimp-curving external window sills

External window sills are curved by means of crimp-curving, which is a relatively less expensive option compared to folding. There is also the advantage that the external window sills are formed at an angle of 105° (all angles) in order to drain away the water.

They can be made from steel, aluminum, copper and zinc.

Maximum height is 100 mm and thickness is 1.0 mm.

MINIMAL SIZES (CRIMP-CURVING):

| size A | 25 mm |

| size B | 20 mm |

| size C | 30 mm |

| size D | 15 mm |

| radius | 250 mm |

| angle | 105 ° |

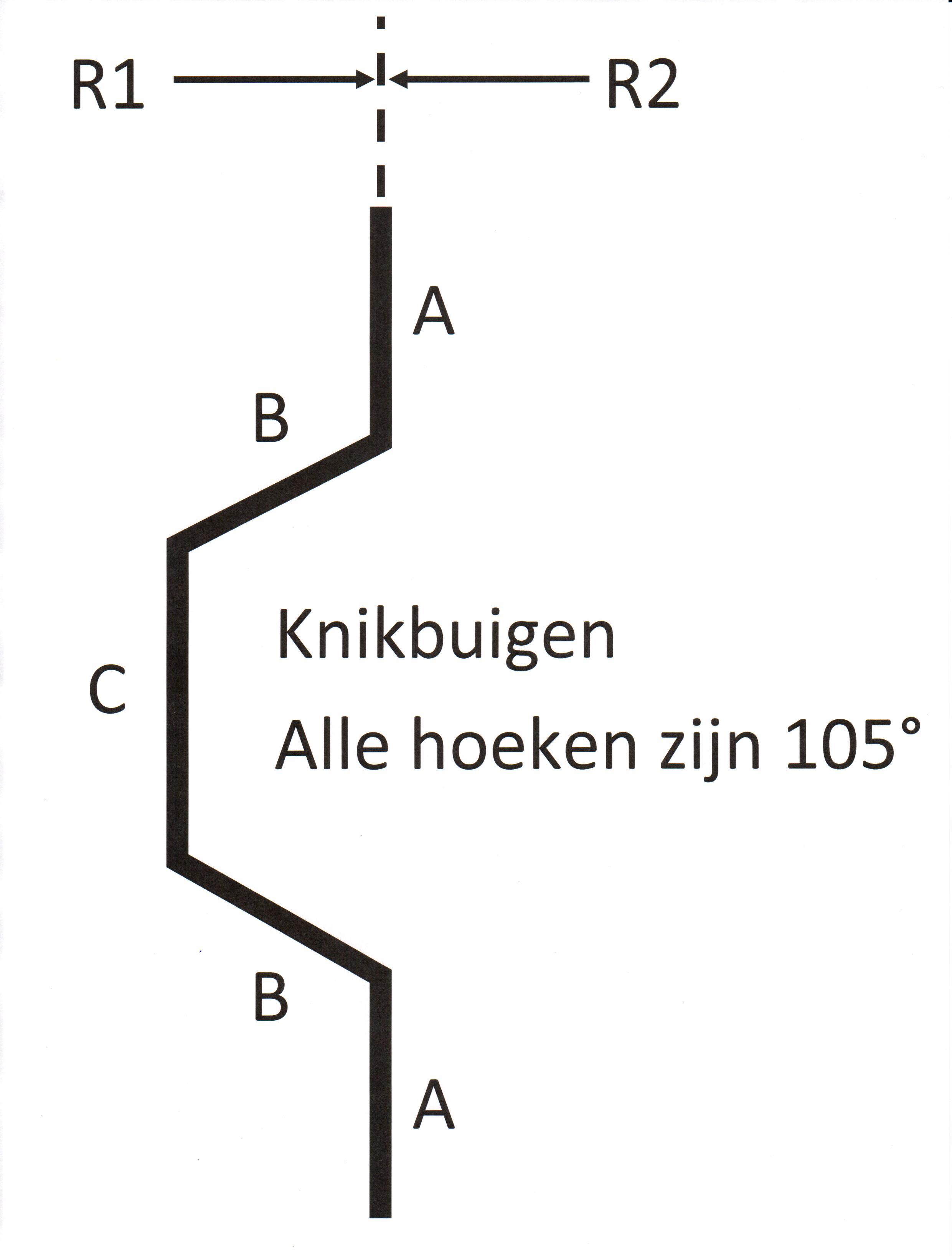

Crimp-curving omegas

Omegas are curved by means of crimp-curving, which is a relatively less expensive backing structure.

The omegas are formed at 105° (all angles) and are then crimp-curved. They can be made from steel and aluminum. Maximum height is 100 mm and thickness is 1.0 mm.

MINIMAL SIZES:

| size A | 25 mm |

| size B | 20 mm |

| size C | 30 mm |

| radius | 250 mm |

| angle | variable |